API 5CT J55 seamless casing tubing

Classification :

Because of the low steel grade of J55, it is used for shallow oil and gas extraction.

Keywords:

API 5CT J55 seamless casing tubing

Product introduction

The J55 API casing or tubing is a relatively common one in oil drilling. Because of the low

steel grade of J55, it is used for shallow oil and gas extraction. Due to its low price among

other grades of steel, it enjoys broader applications. The J55 API casing or tubing is widely

used in the extraction of natural gas and coalbed methane, and can be commonly found in

shallow wells, geothermal wells, and water wells.

J55 Tubing Material can be generally relevant to oil, development, shipbuilding, refining,

aeronautics, electric power, sustenance, paper, compound industry, restorative hardware,

boilers, heat exchangers, metallurgy, etc. 5CT J55 Casing Tubing serves to transport both

unrefined petroleum and gaseous petrol from oil and gas layer to the surface pipeline

subsequent to boring is finished. It can shoulder the weight created by the misuse procedure.

Specification

| Pipe Casing Sizes, Oilfield Casing Sizes & Casing Drift Sizes | |

| Outer Diameter (Casing Pipe Sizes) | 4 1/2"-20", (114.3-508mm) |

| Standard Casing Sizes | 4 1/2"-20", (114.3-508mm) |

| Thread Type | Buttress thread casing, Long round thread casing, Short round thread casing |

| Function | It can protect the tubing pipe. |

Dimension Standard of API 5CTQ J-55 Tubing

| Size | Weight | Outside Diameter | Wall Thickness | End Finish | ||

| Grade | ||||||

| in | mm | in | mm | J55 K55 |

||

| 4 1/2 | 9.50 | 4.500 | 114.3 | 0.205 | 5.21 | PS |

| 10.50 | 0.224 | 5.69 | PSB | |||

| 11.60 | 0.250 | 6.35 | PSLB | |||

| 13.50 | 0.290 | 7.37 | – | |||

| 15.10 | 0.337 | 9.56 | – | |||

| 5 | 11.50 | 5.00 | 127.00 | 0.220 | 5.59 | PS |

| 13.00 | 0.253 | 6.43 | PSLB | |||

| 15.00 | 0.296 | 7.52 | PSLB | |||

| 18.00 | 0.362 | 9.19 | – | |||

| 21.40 | 0.437 | 11.10 | – | |||

| 23.20 | 0.478 | 12.14 | – | |||

| 24.10 | 0.500 | 12.70 | – | |||

| 5 1/2 | 14.00 | 5.500 | 139.7 | 0.244 | 6.20 | PS |

| 15.50 | 0.275 | 6.98 | PSLB | |||

| 17.00 | 0.304 | 7.72 | PSLB | |||

| 20.00 | 0.361 | 9.17 | – | |||

| 23.00 | 0.415 | 10.54 | – | |||

| 6 5/8 | 20.00 | 6.625 | 168.28 | 0.288 | 7.32 | PSLB |

| 24.00 | 0.352 | 8.94 | PSLB | |||

| 28.00 | 0.417 | 10.59 | – | |||

| 32.00 | 0.475 | 12.06 | – | |||

| 7 | 17.00 | 7.00 | 177.80 | 0.231 | 5.87 | – |

| 20.00 | 0.272 | 6.91 | PS | |||

| 23.00 | 0.317 | 8.05 | PSLB | |||

| 26.00 | 0.362 | 9.19 | PSLB | |||

| 29.00 | 0.408 | 10.36 | – | |||

| 32.00 | 0.453 | 11.51 | – | |||

| 35.00 | 0.498 | 12.65 | – | |||

| 38.00 | 0.540 | 13.72 | – | |||

| 7 5/8 | 24.00 | 7.625 | 193.68 | 0.300 | 7.62 | – |

| 26.40 | 0.328 | 8.33 | PSLB | |||

| 29.70 | 0.375 | 9.52 | – | |||

| 33.70 | 0.430 | 10.92 | – | |||

| 39.00 | 0.500 | 12.70 | – | |||

| 42.80 | 0.562 | 14.27 | – | |||

| 45.30 | 0.595 | 15.11 | – | |||

| 47.10 | 0.625 | 15.88 | – | |||

| 8 5/8 | 24.00 | 8.625 | 219.08 | 0.264 | 6.71 | PS |

| 28.00 | 0.304 | 7.72 | – | |||

| 32.00 | 0.352 | 8.94 | PSLB | |||

| 36.00 | 0.400 | 10.16 | PSLB | |||

| 40.00 | 0.450 | 11.43 | – | |||

| 44.00 | 0.500 | 12.70 | – | |||

| 49.00 | 0.557 | 14.15 | – | |||

| 9 5/8 | 32.30 | 9.625 | 244.48 | 0.312 | 7.92 | – |

| 36.00 | 0.352 | 8.94 | PSLB | |||

| 40.00 | 0.395 | 10.03 | PSLB | |||

| 43.50 | 0.435 | 11.05 | – | |||

| 47.00 | 0.472 | 11.99 | – | |||

| 53.50 | 0.545 | 13.84 | – | |||

| 58.40 | 0.595 | 15.11 | – | |||

| 10 3/4 | 32.75 | 10.75 | 273.05 | 0.279 | 7.09 | – |

| 40.50 | 0.350 | 8.89 | PSB | |||

| 15.50 | 0.400 | 10.16 | PSB | |||

| 51.00 | 0.450 | 11.43 | PSB | |||

| 55.50 | 0.495 | 12.57 | – | |||

| 60.70 | 0.545 | 13.84 | – | |||

| 65.70 | 0.595 | 15.11 | – | |||

| 13 3/8 | 48.00 | 13.375 | 339.73 | 0.330 | 8.38 | – |

| 54.50 | 0.380 | 9.65 | PSB | |||

| 61.00 | 0.430 | 10.92 | PSB | |||

| 68.00 | 0.480 | 12.19 | PSB | |||

| 72.00 | 0.514 | 13.06 | – | |||

| 16 | 65.00 | 16 | 406.40 | 0.375 | 9.53 | – |

| 75.00 | 0.438 | 11.13 | PSB | |||

| 84.00 | 0.495 | 12.57 | PSB | |||

| 109.00 | 0.656 | 16.66 | P | |||

| 18 5/8 | 87.50 | 18.625 | 473.08 | 0.435 | 11.05 | PSB |

| 20 | 94.00 | 20 | 508.00 | 0.438 | 11.13 | PSLB |

| 106.50 | 0.500 | 12.70 | PSLB | |||

| 133.00 | 0.635 | 16.13 | PSLB | |||

Technical data

Chemical Composition

| Grade | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≤ | Ni≤ | Cu≤ | Mo≤ | V≤ | Als≤ |

| API 5CT J55 | 0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

0.020 |

| API 5CT K55 | 0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

0.020 |

| API 5CT N80 | 0.34-0.38 |

0.20-0.35 |

1.45-1.70 |

0.020 |

0.015 |

0.15 |

/ |

/ |

/ |

0.11-0.16 |

0.020 |

| API 5CT L80 | 0.15-0.22 |

1.00 |

0.25-1.00 |

0.020 |

0.010 |

12.0-14.0 |

0.20 |

0.20 |

/ |

/ |

0.020 |

| API 5CT J P110 | 0.26-035 |

0.17-0.37 |

0.40-0.70 |

0.020 |

0.010 |

0.80-1.10 |

0.20 |

0.20 |

0.15-0.25 |

0.08 |

0.020 |

Mechanical Properties

|

Steel Grade |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

|

API 5CT J55 |

379-552 |

≥517 |

|

API 5CT K55 |

≥655 |

≥517 |

|

API 5CT N80 |

552-758 |

≥689 |

|

API 5CT L80 |

552-655 |

≥655 |

|

API 5CT P110 |

758-965 |

≥862 |

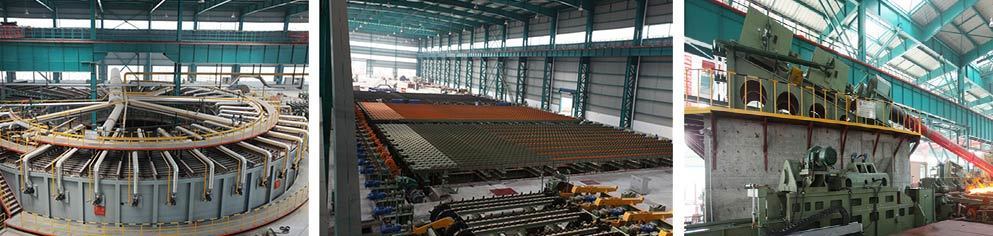

Equipment

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory.

2)High quality product and good price.

3)Good Pre-sale、on sale and after sales service.

4)Short delivery time.

5)Exported all over the world, with rich experience.

Package

FAQ:

Q:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Factory

The factory covers an area of nearly 60000 square meters and has processing equipment such as large shear machines, circular shear machines, straightening machines, annealing furnaces, punching and shearing lines. The company has not only established long-term strategic cooperation relationships with more than 600 domestic large and medium-sized enterprises such as FAW, China National Heavy Duty Truck Group, Sinopec, and Inspur Group. Our products are also exported to over 60 countries and regions in Europe, the Americas, the Middle East, Southeast Asia, and Australia. The products are widely used in industries such as mechanical manufacturing, electrical appliances, electronics, automobiles, insulation, molds, aerospace, military, construction, printing, food, etc

The company implements full process quality control, has a strict quality control system, and closely monitors every step of storage, inspection, and packaging. No negligence is allowed, and unqualified products are not allowed to enter the warehouse. The company has established detailed supplier records and regularly evaluates supply quality. We solemnly promise that if the service is not good, there will be rewards for reporting; If the quality exceeds the standard, the loss will be my package; If the quantity is incorrect, if one is missing, make up ten; If the product is not satisfactory, it will be returned unconditionally.

RELATED PRODUCTS

GET A FREE QUOTE