ASTM A106 Gr.B carbon seamless steel pipe

Classification :

are made by killing steel along with the first melting process being an electric furnace,

basic oxygen, and open hearth and mixed with a single refining.

They are given hot treatment using cold drawn pipe and steel cast in ingots is permissible.

Keywords:

ASTM A106 Gr.B carbon seamless steel pipe

Product introduction

Carbon Steel Pipes (A106 Gr B Pipes) is one of the most common products that are used in the

development of gas or oil refineries, petrochemical plants, ships, boilers and power plants. They

are used at the place where water or oil is stored and search for a narrow space to be flown smoothly.

Generally, they are the big need of industries all around the world. They are also used where the piping

should transport gases and fluid that absorb higher pressure and temperature levels. They are divided

into two grades, first is A, the last one is B, but surprisingly their uses and specifications are almost same.

The total thickness of these carbon steel pipes is from ¼ to 30” and they are also differentiated in schedules,

shapes, and designs even dimensions too. The wall thickness of them is out of XXH such as 4 to 24 OD, 3 walls

to 18 OD and 2 walls to 8 OD.

Carbon Steel Pipes (A106 Gr B Pipes) are made by killing steel along with the first melting process being an electric

furnace, basic oxygen, and open hearth and mixed with a single refining. They are given hot treatment using cold

drawn pipe and steel cast in ingots is permissible.

ASTM A106 Gr-B Carbon Seamless Steel Pipe Specification

SPECIFICATIONS : ASTM A106 ASME SA106

DIMENSIONS : ASTM, ASME and API

SIZE : 1/2” NB to 36” NB

THICKNESS : 3-12mm

SCHEDULES : SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

TYPE : Seamless / ERW / Welded

FORM : Round, Hydraulic Etc

LENGTH : Min 3 Meters, Max18 Meters, or according to customer’s requirement

END : Plain End, Beveled End, Treaded

Technical data

ASTM A106 Gr-B Carbon Seamless Steel Pipe Chemical Composition

| ASTM A106 – ASME SA106 seamless carbon steel pipe – chemical composition, % | ||||||||||

| Element | C max |

Mn | P max |

S max |

Si min |

Cr max (3) |

Cu max (3) |

Mo max (3) |

Ni max (3) |

V max (3) |

| ASTM A106 Grade A | 0.25 (1) | 0.27-0.93 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| ASTM A106 Grade B | 0.30 (2) | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

| ASTM A106 Grade C | 0.35 (2) | 0.29-1.06 | 0.035 | 0.035 | 0.10 | 0.40 | 0.40 | 0.15 | 0.40 | 0.08 |

ASTM A106 Gr-B Carbon Seamless Steel Pipe Mechanical & Physical Properties

| ASTM A106 pipe | A106 Grade A | A106 Grade B | A106 Grade C |

| Tensile Strength, min., psi | 48,000 | 60,000 | 70,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 40,000 |

ASTM A106 Gr-B Carbon Seamless Steel Pipe Dimension Tolerances

| Pipe Type | Pipe Sizes | Tolerances | |

| Cold Drawn | OD | ≤48.3mm | ±0.40mm |

| ≥60.3mm | ±1%mm | ||

| WT | ±12.5% | ||

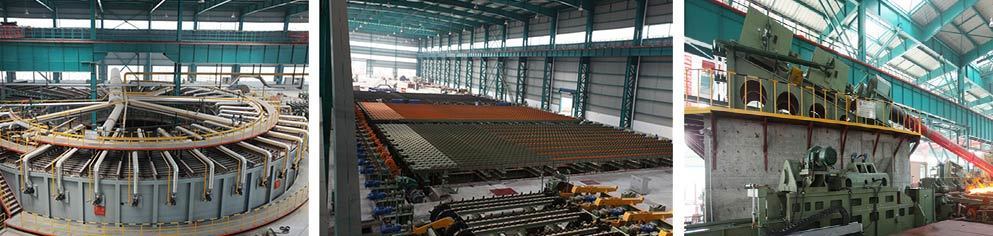

Equipment

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory.

2)High quality product and good price.

3)Good Pre-sale、on sale and after sales service.

4)Short delivery time.

5)Exported all over the world, with rich experience.

Package

FAQ:

Q:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Factory

The factory covers an area of nearly 60000 square meters and has processing equipment such as large shear machines, circular shear machines, straightening machines, annealing furnaces, punching and shearing lines. The company has not only established long-term strategic cooperation relationships with more than 600 domestic large and medium-sized enterprises such as FAW, China National Heavy Duty Truck Group, Sinopec, and Inspur Group. Our products are also exported to over 60 countries and regions in Europe, the Americas, the Middle East, Southeast Asia, and Australia. The products are widely used in industries such as mechanical manufacturing, electrical appliances, electronics, automobiles, insulation, molds, aerospace, military, construction, printing, food, etc

The company implements full process quality control, has a strict quality control system, and closely monitors every step of storage, inspection, and packaging. No negligence is allowed, and unqualified products are not allowed to enter the warehouse. The company has established detailed supplier records and regularly evaluates supply quality. We solemnly promise that if the service is not good, there will be rewards for reporting; If the quality exceeds the standard, the loss will be my package; If the quantity is incorrect, if one is missing, make up ten; If the product is not satisfactory, it will be returned unconditionally.

RELATED PRODUCTS

GET A FREE QUOTE