T8-T10A hot rolled steel round bars

Classification :

Keywords:

T8-T10A hot rolled steel round bars information

Tool steels are high quality steels developed with controlled chemical composition to form properties essential for working and shaping of other materials. They are normally delivered to the suppliers in the soft annealed condition, which makes it easy for the manufacturer to machine the material with cutting tool for different applications.AISI T8 tool steel is a tungsten-cobalt-vanadium high-speed tool steel. The following datasheet will provide an overview of grade T8 tool steels.

Chemical and Mechanical

Chemical Composition

The chemical composition of T8 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Tungsten, W | 13.25-14.75 |

| Cobalt, Co | 4.25-5.75 |

| Chromium, Cr | 3.75-4.5 |

| Vanadium, V | 1.80-2.40 |

| Carbon, C | 0.75-0.85 |

| Molybdenum, Mo | 0.4-1 |

| Nickel, Ni | 0.3 |

| Copper, Cu | 0.25 |

| Manganese, Mn | 0.2-0.4 |

| Silicon, Si | 0.2-0.4 |

| Phosphorus, P | 0.03 |

| Sulfur, S | 0.03 |

Physical Properties

The following table shows the physical properties of T8 tool steels.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.43 g/cm3 | 0.267 lb/in3 |

Mechanical Properties

The mechanical properties of T8 tool steels are displayed in the following table.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 1158 MPa | 167.95 ksi |

| Elongation | 15% | 15% |

| Modulus of elasticity | 190-210 GPa | 27557- 30457 ksi |

| Poisson’s ratio | 0.27-0.3 | 0.27-0.3 |

Thermal Properties

The thermal properties of T8 tool steels are given in the following table

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient | 16-17 µm/m°C | 8.8-9.4 µin/in°F |

| Thermal conductivity | 16 W/mK | 110 BTU.in/hrft².°F |

T8 Range of products

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Cross Reference Table(Equivalent Grade

| Grade | Standard | Country | Application |

|---|---|---|---|

| T8 | ASTM | USA | High-Speed Tool Steel |

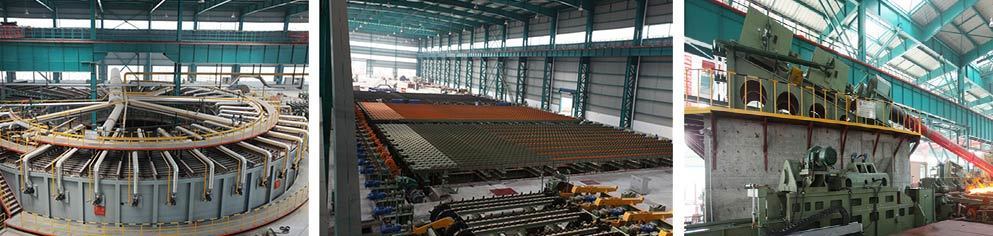

Equipment

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory.

2)High quality product and good price.

3)Good Pre-sale、on sale and after sales service.

4)Short delivery time.

5)Exported all over the world, with rich experience.

Package

FAQ:

Q:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Factory

The factory covers an area of nearly 60000 square meters and has processing equipment such as large shear machines, circular shear machines, straightening machines, annealing furnaces, punching and shearing lines. The company has not only established long-term strategic cooperation relationships with more than 600 domestic large and medium-sized enterprises such as FAW, China National Heavy Duty Truck Group, Sinopec, and Inspur Group. Our products are also exported to over 60 countries and regions in Europe, the Americas, the Middle East, Southeast Asia, and Australia. The products are widely used in industries such as mechanical manufacturing, electrical appliances, electronics, automobiles, insulation, molds, aerospace, military, construction, printing, food, etc

The company implements full process quality control, has a strict quality control system, and closely monitors every step of storage, inspection, and packaging. No negligence is allowed, and unqualified products are not allowed to enter the warehouse. The company has established detailed supplier records and regularly evaluates supply quality. We solemnly promise that if the service is not good, there will be rewards for reporting; If the quality exceeds the standard, the loss will be my package; If the quantity is incorrect, if one is missing, make up ten; If the product is not satisfactory, it will be returned unconditionally.

RELATED PRODUCTS

GET A FREE QUOTE