34CrNiMo6 hot rolled steel round bars

Classification :

Keywords:

1. 34CrNiMo6 hot rolled steel round bars Application

EN DIN 34CrNiMo6 steel is used to make tools which demands good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

is reliable to supply engineering 34CrNiMo6 steels / 1.6582 engineering alloy steels. Please tell us your detailed requirements and have the best offer soon.

2. Chemical and Mechanical

34CrNiMo6 Chemical composition and Equivalents steel grade properties

| BS EN 10083 – 3:2006 | 34CrNiMo6 | C | Si | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.40 Max | 0.50-0.80 | 0.025 max | 0.035 max | 1.30-1.70 | 0.15-0.30 | 1.30-1.70 |

34CrNiMo6 Steel Mechanical Properties

| Diameter(mm) | < 16 | 16~ 40 | 40~100 | 100~160 | 160 ~250 |

| Thickness t (mm) | < 8 | 8~20 | 20~60 | 60~100 | 100~160 |

| Tensile strength Rm (N/mm2) | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A (%) | 9 min | 10 Min | 11 Min | Min 12 | 13 Min |

| Reduction of area Z (%) | 40Min | 45 Min | 50Min | 55Min | 55MIn |

| Toughness CVN (J) | 35Min | 45Min | 45Min | 45Min | 45 Min |

| Yield strength Re (N/mm²) | 1000 Min | 900 Min | 800 Min | 700 Min | 600 Min |

EN 34CrNiMo6 Steel Standards And Equivalents

| BS EN 10083 -3: 2006 | 34CrNiMo6 / 1.6582 | ASTM A29: 2004 | 4337 |

| BS EN 10250 – 3: 2000 |

3. EN/DIN 34CrNiMo6 Steel Chemical Composition Properties

| BS EN 10083 – 3:2006 | 34CrNiMo6 /1.6582 |

C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.025 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| BS EN 10250-3:2000 | C | Mn | Si | P | S | Cr | Mo | Ni | |

| 0.30-0.38 | 0.5-0.8 | 0.40 max | 0.035 max | 0.035 max | 1.3-1.7 | 0.15-0.30 | 1.3-1.7 | ||

| ASTM A29: 2004 | 4337 | C | Mn | Si | P | S | Cr | Mo | Ni |

| 0.30-0.40 | 0.6-0.8 | 0.20-0.35 | 0.035 max | 0.040 max | 0.70-0.90 | 0.20-0.30 | 1.65-2.00 |

4.Mechanical Properties of EN/DIN 34CrNiM06 / 1.6582 Alloy Steel

| Properties | < 16 | >16 – 40 | >40 – 100 | >100 – 160 | >160 – 250 |

| Thickness t [mm] | < 8 | 8<t<20 | 20<t<60 | 60<t<100 | 100<t<160 |

| Yield strength Re [N/mm²] | min. 1000 | min. 900 | min. 800 | min. 700 | min. 600 |

| Tensile strength Rm [N/mm2] | 1200 – 1400 | 1100 – 1300 | 1000 – 1200 | 900 – 1100 | 800 – 950 |

| Elongation A [%] | min. 9 | min. 10 | min. 11 | min. 12 | min. 13 |

| Reduction of area Z [%] | min. 40 | min. 45 | min. 50 | min. 55 | min. 55 |

| Toughness CVN [J] | min. 35 | min. 45 | min. 45 | min. 45 | min. 45 |

5.Heat Treatment of 34CrNiMo6 Engineering Steel

Quenched and Tempered (Q+T) of 34CrNiMo6 Steel

- Heat 34CrNiMo6 round steel slowly to the temperature of 850°C;

- Soak at this hardening temperature quench in oil;

- Temper as soon as 34CrNiMo6 steels reach room temperature.

- Heat uniformly to the suitable temperature;

- Withdraw from the furnace and cool in the air.

- The usual tempering temperature is 600°C which depending on the actual requirements.

6.Forging of DIN 34CrNiMo6 / 1.6582 Steel

Hot forming temperature: 1100-900oC.

7.Machinability of Steel 34CrNiMo6

Machining is best done with this 1.6582 alloy steel in the annealed or normalized and tempered condition. It can be machined by all conventional methods.

8.Welding

The alloy materials can be fusion or resistance welded. Preheat and post heat weld procedures should be followed when welding this alloy by established methods.

9.Application

EN DIN 34CrNiMo6 steel is used to make tools which demands good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

is reliable to supply engineering 34CrNiMo6 steels / 1.6582 engineering alloy steels. Please tell us your detailed requirements and have the best offer soon.

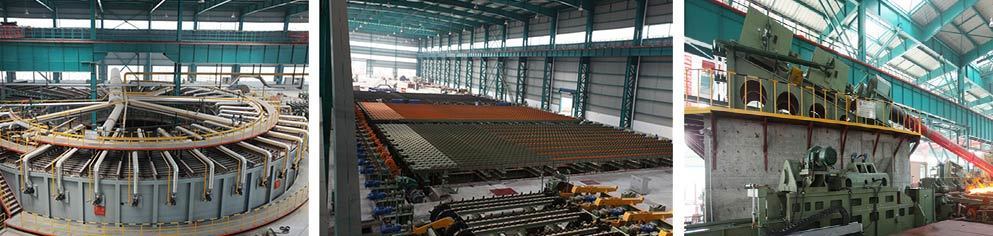

Equipment

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory.

2)High quality product and good price.

3)Good Pre-sale、on sale and after sales service.

4)Short delivery time.

5)Exported all over the world, with rich experience.

Package

FAQ:

Q:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Factory

The factory covers an area of nearly 60000 square meters and has processing equipment such as large shear machines, circular shear machines, straightening machines, annealing furnaces, punching and shearing lines. The company has not only established long-term strategic cooperation relationships with more than 600 domestic large and medium-sized enterprises such as FAW, China National Heavy Duty Truck Group, Sinopec, and Inspur Group. Our products are also exported to over 60 countries and regions in Europe, the Americas, the Middle East, Southeast Asia, and Australia. The products are widely used in industries such as mechanical manufacturing, electrical appliances, electronics, automobiles, insulation, molds, aerospace, military, construction, printing, food, etc

The company implements full process quality control, has a strict quality control system, and closely monitors every step of storage, inspection, and packaging. No negligence is allowed, and unqualified products are not allowed to enter the warehouse. The company has established detailed supplier records and regularly evaluates supply quality. We solemnly promise that if the service is not good, there will be rewards for reporting; If the quality exceeds the standard, the loss will be my package; If the quantity is incorrect, if one is missing, make up ten; If the product is not satisfactory, it will be returned unconditionally.

RELATED PRODUCTS

GET A FREE QUOTE