Seamless Alloy Steel Tube

Classification :

chemical plants, fertilizers plants, petrochemicals plants and sugar mills etc.

Keywords:

Seamless Alloy Steel Tube

Product introduction

Seamless Alloy Steel Tube

Type: Alloy Pipe, Alloy Tube, Alloy Steel Pipe, Alloy Steel Tube

Application: In Petroleum, Aerospace, Chemical, Power, Boilers, Military Industry

Specification: Outside Diameter: 1/8'' ~ 26''

Wall Thickness: SCH 30, 30, 40, 60, 80, 120, 140, 160, XS, XXS, STD

Length: Single Random, Double Random, Cut Length max to 23m

Standard & Grade: ASTM A333, A335 P5/P9/P11/P22/P91, DIN 17175, JIS G3458

End: Plain End, Beveled End, Thread End

Packing: Bundled with Hemp Rope/In Bulk

Alloy pipe is a kind of seamless steel pipe, its performance is much higher than that of general seamless steel pipe, because this type of steel pipe contains more Cr, its high temperature resistance, low temperature resistance, corrosion resistance performance is much better than other Steel pipe , so the alloy pipe is widely used in petroleum, aerospace, chemical, electric power, boiler, military and other industries.

| Product | SEAMLESS / ERW / SAW ALLOY STEEL PIPE |

| Dimension | 6 mm - 1080 mm |

| Thickness | 1mm - 135 mm |

| Length | 3 m - 12 m or according to the requirements of clients |

| Standard | ASTM GB DIN |

| Steel grade | A106/53/179/214/192/210 A/B/C ST37.2/35.4/35.8/52/52.3/52.4/42/45 10# 20# 45# P2, P12, P11, P22, P5, P9, P91 T2, T11,T5,T9,T22, 4140, 12CrMo, 15CrMo, 12Cr2Mo, 1Cr5Mo, 2CrMo4, 1Cr9Mo, 10CrMo910, etc. |

| Trade terms | FOB/CIF/CFR |

| Payment terms | T/T, L/C |

| Delivery time | 10 or according to the real quantity of the tubes |

| Surface treatment | Black painting Varnish painting 3PE Hot galvanized or other coating according to your requirements Bare tube |

| End of tubes | Beveled, plain, thread, plastic caps |

| Inspection | Ultrasonic examination, eddy inspection, hydrosttic testing etc. |

| Package | Bundles, lossen or according to your requirements |

| Certificate | API 5L/5CT, ISO, PED etc. |

Technical data

Chemical Composition

| C, % | Mn, % | P, % | S, % | Si, % | Cr, % | Mo, % |

| 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

Mechanical Properties

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

| 415 min | 205 min | 30 min |

Outside Diameter & Tolerance

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Outside Diameter, inch | Tolerance, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

Wall thickness & Tolerance

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Outside Diameter, inch | Tolerance, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Standard

ASTM A335--for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

ASTM A519--for Seamless Carbon and Alloy Steel Mechanical Tubing

ASTM A213--for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM ASME (S)A-335/(S)A-335M Grade and Chemical Composition

| Grade | UNS | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | - | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | - | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50 | 1.90~2.60 | 0.87~1.13 |

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.020 | 0.010 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.020 | 0.010 | 0.50 | 8.50~9.50 | 0.30~0.60 |

Note: (S)A335 P91 other chemical composition are : V 0.18~0.25; N 0.030~0.070; Ni ≤ 0.40; Al ≤ 0.04 ; Nb 0.06~0.10

(S)A335 P92 other chemical composition are : V 0.15~0.25; N 0.030~0.070; Ni ≤ 0.40; Al ≤ 0.04 ; Nb 0.04~0.09; W 1.5~2.00 ; B 0.001~0.006

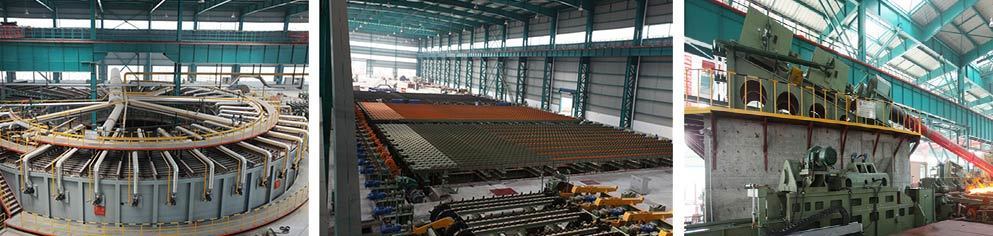

Equipment

Why Choose Us?

1)The products can be made completely according to the customer's requirements, and we have our own factory.

2)High quality product and good price.

3)Good Pre-sale、on sale and after sales service.

4)Short delivery time.

5)Exported all over the world, with rich experience.

Package

FAQ:

Q:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q:Do you offer after-sales services?

A:Certainly. If you have any questions, please feel free to contact us. We shall certainly do it to your satisfaction.

Factory

The factory covers an area of nearly 60000 square meters and has processing equipment such as large shear machines, circular shear machines, straightening machines, annealing furnaces, punching and shearing lines. The company has not only established long-term strategic cooperation relationships with more than 600 domestic large and medium-sized enterprises such as FAW, China National Heavy Duty Truck Group, Sinopec, and Inspur Group. Our products are also exported to over 60 countries and regions in Europe, the Americas, the Middle East, Southeast Asia, and Australia. The products are widely used in industries such as mechanical manufacturing, electrical appliances, electronics, automobiles, insulation, molds, aerospace, military, construction, printing, food, etc

The company implements full process quality control, has a strict quality control system, and closely monitors every step of storage, inspection, and packaging. No negligence is allowed, and unqualified products are not allowed to enter the warehouse. The company has established detailed supplier records and regularly evaluates supply quality. We solemnly promise that if the service is not good, there will be rewards for reporting; If the quality exceeds the standard, the loss will be my package; If the quantity is incorrect, if one is missing, make up ten; If the product is not satisfactory, it will be returned unconditionally.

RELATED PRODUCTS

GET A FREE QUOTE